CNC Precision Machining Parts Supplier

Understanding CNC Precision Machining

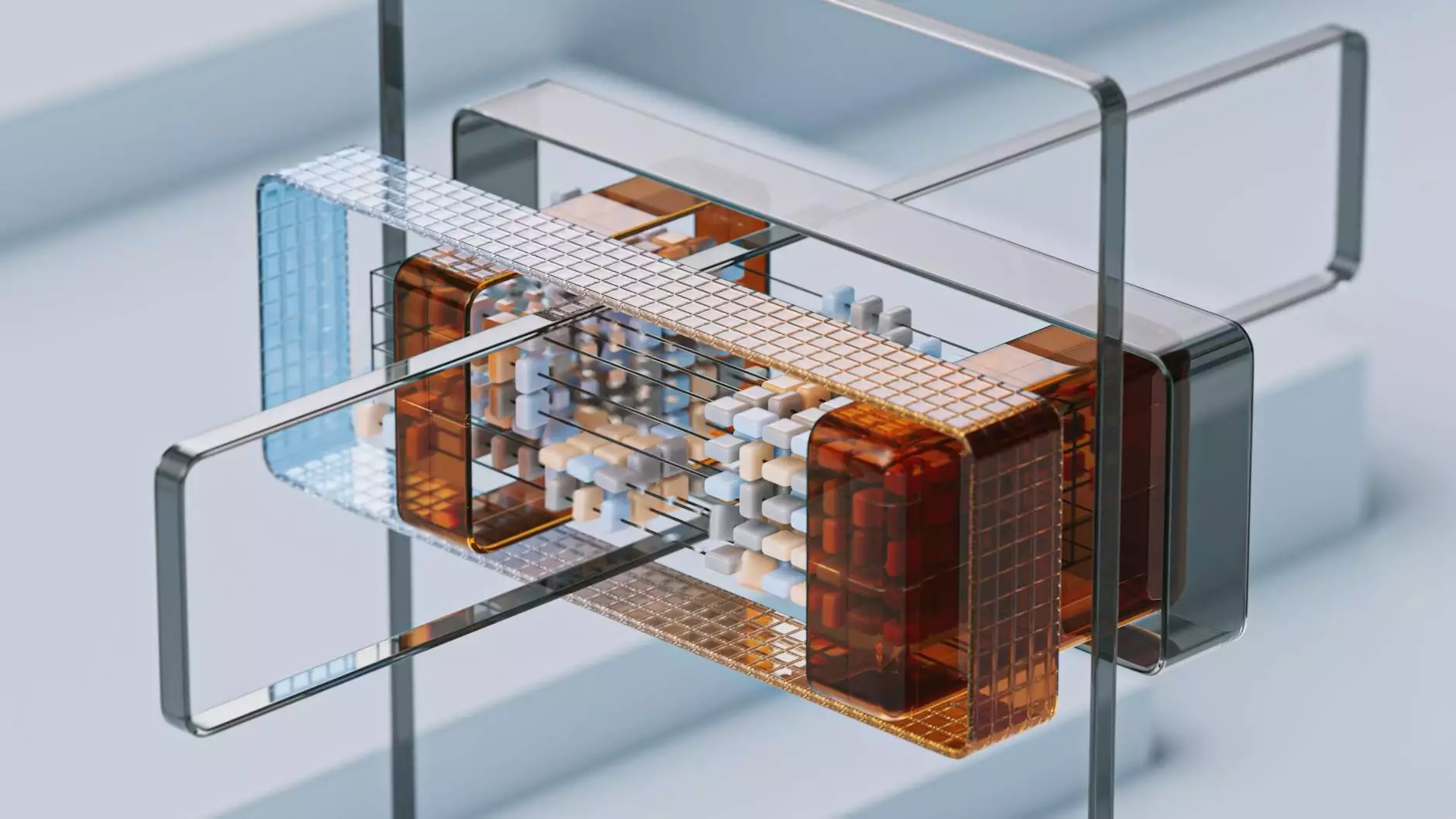

CNC precision machining is a manufacturing process that utilizes computer-controlled machines to create parts with remarkable accuracy and efficiency. The term "CNC" stands for Computer Numeric Control, and it refers to the automated control of machining tools by means of a computer. This technology has revolutionized the manufacturing industry by allowing for the production of complex parts that meet stringent specifications across various sectors, including aerospace, automotive, and medical fields.

The Advantages of CNC Machining

The benefits of CNC precision machining extend far beyond simple automation. Here are some key advantages:

- Enhanced Precision: CNC machines can achieve tolerances of ±0.002 mm, which is crucial for parts that must fit together perfectly.

- Repeatability: Once a program is written and tested, the machine can produce countless identical parts with absolutely no deviation.

- Complex Shapes: CNC machines can create intricate designs that would be impossible or very time-consuming to achieve with manual methods.

- Efficiency: Automated operations reduce production times, allowing for quicker turnaround on projects.

- Reduced Waste: Advanced software optimizes material usage, significantly lowering waste and costs.

Applications of CNC Precision Machining Parts

As a leading cnc precision machining parts supplier, DeepMould serves a diverse range of industries that require high-quality components. Some notable applications include:

- Aerospace: Lightweight and strong components are essential in aviation for fuel efficiency and safety.

- Automotive: Precision parts are crucial for engine performance, safety features, and overall vehicle reliability.

- Medical Devices: The medical field requires components that are precise and can withstand rigorous sterilization processes.

- Electronics: From smartphone parts to complex circuit boards, CNC machining meets the high demands of the electronics market.

- Industrial Equipment: Custom made components for machinery that enhance efficiency and productivity in manufacturing processes.

Choosing the Right CNC Precision Machining Parts Supplier

When selecting a cnc precision machining parts supplier, it's vital to consider several factors to ensure you find the right partner for your manufacturing needs. Here are essential aspects to evaluate:

1. Quality Assurance

Quality is non-negotiable in precision machining. Look for suppliers who have robust quality control processes and certifications, such as ISO 9001. A trusted supplier will provide guarantees that their products meet your specifications consistently.

2. Technological Capability

The best CNC suppliers invest in the latest technology and equipment. This includes not just the machines, but also advanced software that enhances design capabilities and manufacturing processes.

3. Material Choices

A reputable supplier should offer a wide range of materials, including metals like aluminum, stainless steel, and titanium, as well as plastics and composites. This versatility allows you to choose the best material for your specific application.

4. Lead Times and Flexibility

In today’s fast-paced market, delivery times can make or break a project. Ensure your supplier can meet your deadlines and has a proven track record of flexibility in handling rush orders or changes in specifications.

5. Customer Service and Support

A strong partnership hinges on effective communication. Select a supplier with dedicated customer service that can assist you with any inquiries or issues that may arise during production.

The Importance of Certifications in CNC Machining

Certifications validate the quality and reliability of a cnc precision machining parts supplier. Some important certifications include:

- ISO 9001: A standard that ensures consistent quality management systems.

- ISO 13485: Specifically for medical device manufacturing, this ensures adherence to safety and quality standards.

- AS9100: Pertinent to aerospace standards, affirming the supplier's commitment to quality in the aerospace sector.

DeepMould - Your Trusted CNC Precision Machining Parts Supplier

At DeepMould, we take pride in being a premier cnc precision machining parts supplier. Our commitment to quality, innovation, and customer satisfaction set us apart in the industry. Here’s why choosing DeepMould will benefit your business:

Extensive Expertise

With years of experience in the CNC machining industry, our skilled team understands the intricacies of precision engineering. We leverage our expertise to ensure optimal designs and efficient production processes that meet the most demanding specifications.

State-of-the-Art Facilities

Our manufacturing facilities are equipped with cutting-edge CNC machines, capable of producing high-quality parts at scale. We continuously update our machinery and technology to stay at the forefront of the industry.

Tailored Solutions

We recognize that each project has unique requirements. Our team works closely with clients to develop tailored solutions that meet their specific needs, ensuring satisfaction and success.

Conclusion

The world of manufacturing is constantly evolving, and CNC precision machining is at the forefront of this transformation. As businesses and industries demand greater efficiency, precision, and customization, partnering with a trusted cnc precision machining parts supplier like DeepMould can significantly enhance your manufacturing capabilities. Let us help you lead the way into the future of precision engineering.

For more information on how DeepMould can support your machining needs or to request a quote, visit our website at deepmould.net.